Site assessment:Our installation team assesses the site where the crane will be installed to identify any potential hazards or obstacles that could affect the installation process.

Planning:A plan is developed for the crane installation, including the design of the crane foundation, the rigging plan, and the assembly and installation procedures.

Site preparation:The site is prepared for crane installation, including clearing the area, grading the ground, and preparing the crane foundation.

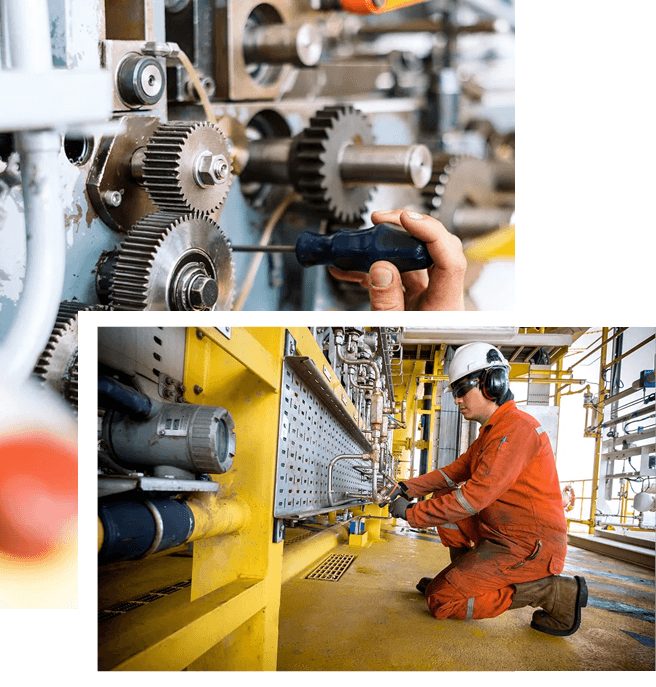

Crane assembly:The crane components are assembled according to the instructions and the installation plan. This may involve the use of cranes, hoists, and other equipment to lift and position the crane components.

Rigging and testing:The crane is rigged, and load testing is conducted to ensure that it meets the load requirements and safety standards.

Electrical and mechanical connections:Electrical and mechanical connections are made to power the crane and ensure that it operates safely and efficiently.

Commissioning:The crane is commissioned, which involves testing all of its operational controls and safety features to ensure that it is safe to operate.

Training:We provides training to crane operators and maintenance personnel to ensure that they understand the proper operation and maintenance procedures.

Documentation:All aspects of the installation process are documented, including the installation plan, load testing results, and commissioning checklist. This documentation is critical for tracking the crane's installation history and compliance with regulatory requirements.