In the world of industrial operations, the safety of personnel and equipment is paramount. Mobile straddle carriers, with their significant role in handling heavy loads, demand meticulous attention to safety protocols. This article will introduce the importance of mobile straddle carrier safety, identifies common hazards during operation, and provides ten essential tips to ensure the secure and efficient use of these powerful machines.

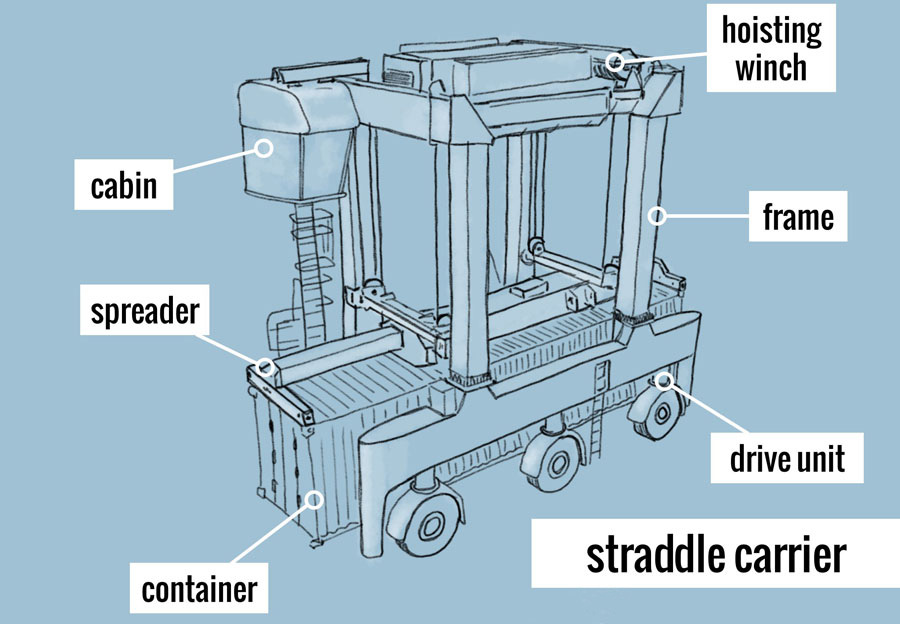

Mobile straddle carriers, designed for the vertical movement and transportation of loads, play a pivotal role in industrial logistics. The sheer size and weight of the loads they handle make safety an absolute priority. Ensuring the well-being of operators and bystanders, as well as preventing damage to valuable loads, underscores the significance of implementing safety measures. A commitment to straddle carrier safety not only safeguards lives but also protects investments and maintains the smooth flow of industrial operations.

Understanding the potential hazards associated with mobile straddle carrier operation is crucial for developing effective safety protocols. Some of the common hazards include:

Toppling

The high center of gravity of mobile straddle carriers makes them susceptible to tipping over, especially when carrying heavy loads or navigating uneven terrain.

Visibility Challenges

Limited visibility from the operator’s cabin can result in blind spots, leading to accidents involving pedestrians, other vehicles, or infrastructure.

Mechanical Failures

Malfunctions in critical components, such as the lifting mechanism or steering system, can pose serious safety risks during straddle crane operation.

Weather Conditions

Adverse weather, such as high winds or rain, can impact the stability and control of mobile straddle carriers, increasing the likelihood of accidents.

Lifting Operations

Mishandling of loads during lifting operations can lead to load instability, causing goods to fall or shift unexpectedly.

Poor Maintenance

Neglecting regular maintenance routines can result in equipment failure, compromising the safety and reliability of mobile straddle carrier.

Inadequate Training

Insufficient training of operators may contribute to errors in judgment or improper use of the equipment, amplifying the risk of accidents.

Comprehensive Training Programs

Prioritize thorough training programs for straddle lift crane operators. Ensure that operators are well-versed in the equipment’s functionalities, safety procedures, and emergency protocols. Regular refresher courses can help reinforce safety awareness.

Routine Equipment Inspections

Implement a rigorous schedule for routine inspections and maintenance. This includes checking critical components, such as brakes, tires, and hydraulic systems. Promptly address any identified issues to prevent potential hazards.

Clear Communication

Establish clear communication channels between mobile straddle crane operators, ground personnel, and other stakeholders. Utilize radio communication systems and visual signals to convey critical information, especially in environments with limited visibility.

Adherence to Load Limits

Strictly adhere to load capacity limits specified by the manufacturer. Overloading straddle lift crane can compromise stability and increase the risk of accidents. Use load charts and indicators to guide safe lifting operations.

Weather Monitoring

Monitor weather conditions regularly and suspend mobile straddle carrier operations during adverse weather events. High winds, heavy rain, or slippery surfaces can jeopardize the stability and control of the equipment.

Enhanced Visibility Features

Retrofit mobile straddle carriers with enhanced visibility features, such as cameras and mirrors, to minimize blind spots. Improved visibility reduces the risk of accidents involving pedestrians, other equipment, or structures.

Advanced Collision Avoidance Systems

Invest in and utilize advanced collision avoidance systems that incorporate sensors and alarms. These systems can detect obstacles in the carrier’s path, providing early warnings to operators and preventing potential collisions.

Pedestrian Safety Measures

Designate pedestrian walkways and enforce strict safety measures for individuals working in proximity to mobile straddle carriers. Implement physical barriers and warning signs to create awareness and prevent accidental collisions.

Emergency Response Plans

Develop and regularly review emergency response plans that outline procedures for various scenarios, including equipment malfunctions, accidents, or adverse weather events. Conduct regular drills to ensure all personnel are familiar with emergency protocols.

Continuous Improvement

Cultivate a culture of continuous improvement by encouraging operators to report accidents, hazards, or equipment issues in a timely manner. Establish a feedback loop to address reported issues and implement corrective measures.

Implementing these 10 tips for mobile straddle transporter operation safety can significantly reduce the risk of accidents, safeguard lives, and contribute to the smooth and efficient flow of industrial operations. In a landscape where precision and reliability are paramount, a commitment to safety is an investment in both the present and the future of industrial excellence.

If you have any questions about mobile straddle carrier, contact us any time!